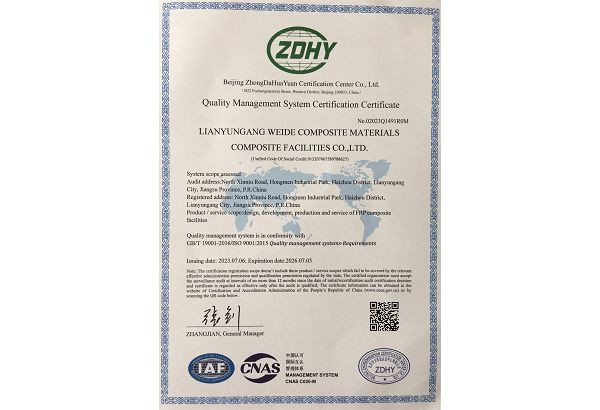

Lianyungang Weide Composite Materials Facilities Co., Ltd. was established in 2001 and is a national high-tech enterprise focusing on the research and manufacturing of high-end composite materials facilities. The company occupies 42 acres of land with a production area of 20,000 square meters and has gathered more than 20 well-trained design and R&D(research and development) technical personnel. With over twenty years of professional dedication, the company has consistently focused on solving core pain points and challenges in the industry, providing systemic solutions for customers. For many years, it has earned wide acclaim and recognition from users.

Weide company's core competitiveness is reflected in having a young, aspiring, and responsible technical R&D team, and has developed four core product series, each product embodying profound technical accumulation and innovation achievements:

Breaking through tradition and leading innovation! With continuous winding FRP pipe production line, Weide spearheads the industry as the first domestic company to master fully independent intellectual property in continuous winding technology. From facilities R&D and process optimization to design services and after-sales services, Weide has built a complete core competency system. The comprehensive system, composed of winding machine, intelligent feeding system, automatic transport system, joint-making system, quality assurance system, and environmental treatment system, accurately delivers fibers, quartz sand, resin, and additives to the surface of steel band molds via computer control, with efficient far IR curing technology and additive manufacturing processes creating layered, dense, and homogeneous structures. It is significantly superior to traditional processes in terms of product quality, production efficiency, mechanical performance, worker workload reduction, and working environment.

Harnessing hydrogen energy and fostering development! High pressure hydrogen storage winding production line earns trust with high stability, automation, and outstanding efficiency. After a decade of meticulous development through in-depth collaboration with hydrogen energy industry leaders, this production line has undergone rigorous high-load testing with an annual output of 30,000 high pressure hydrogen cylinders. Its performance now matches European standards, enabling it to powerfully replace imported products! Four-axis high precision winding machines, automatic loading and unloading machine hands, curing ovens, resin supply systems and other core facilities.

Powering hidden underground, born of precise casting! Centrifugal casting pipe production line employs computer precision control for unsaturated resin, fiberglass, quartz sand, and various auxiliary materials, forming cloth into high-speed rotating molds to achieve high-speed compaction, heating, curing, and demolding cooling. Due to its unique forming process, various materials inside the high-speed rotating mold endure over 50 gravitational accelerations during curing and forming. The pipes molded by this process have excellent compactness and axial compressive strength of up to 95 MPa. It is very suitable for non-excavation urban pipes-pipe-jacking creation.

Fighting corrosion and guarding the lifeline of industry! High pressure epoxy pipe production line is born for harsh conditions. From DN50 to DN1000 pipe diameters, with CNC winding precise shaping, PLC controlled temperature curing oven (room temperature to 180°C) provides a perfect curing heating curve. Unmatched core strengths: fearless of aggressive chemical media, parting ways with anticorrosion maintenance completely; light and strong, excellent pressure resistance, weighing only 1/4-1/5 of steel pipes; ultra-long lifespan design, serving over 50 years, and significant overall cost reduction. It is the most trusted "strong defense" for conveying corrosive media in petrochemical industry and seawater desalination projects.

It provides extreme protection from the breakthrough of domestically produced continuous winding, to replacing imported hydrogen storage equipment; from robust underground pipe network casting, to anticorrosion pipe. Lianyungang Weide Composite Materials Facilities Co., Ltd., each step marks the persistence of independent innovation and the pursuit of excellence. Looking ahead, Weide company will continue to uphold the spirit of craftsmanship, exploring innovation continuously in the forefront field of composite materials equipment, moving firmly toward broader development prospects-taking small steps to reach great distances.